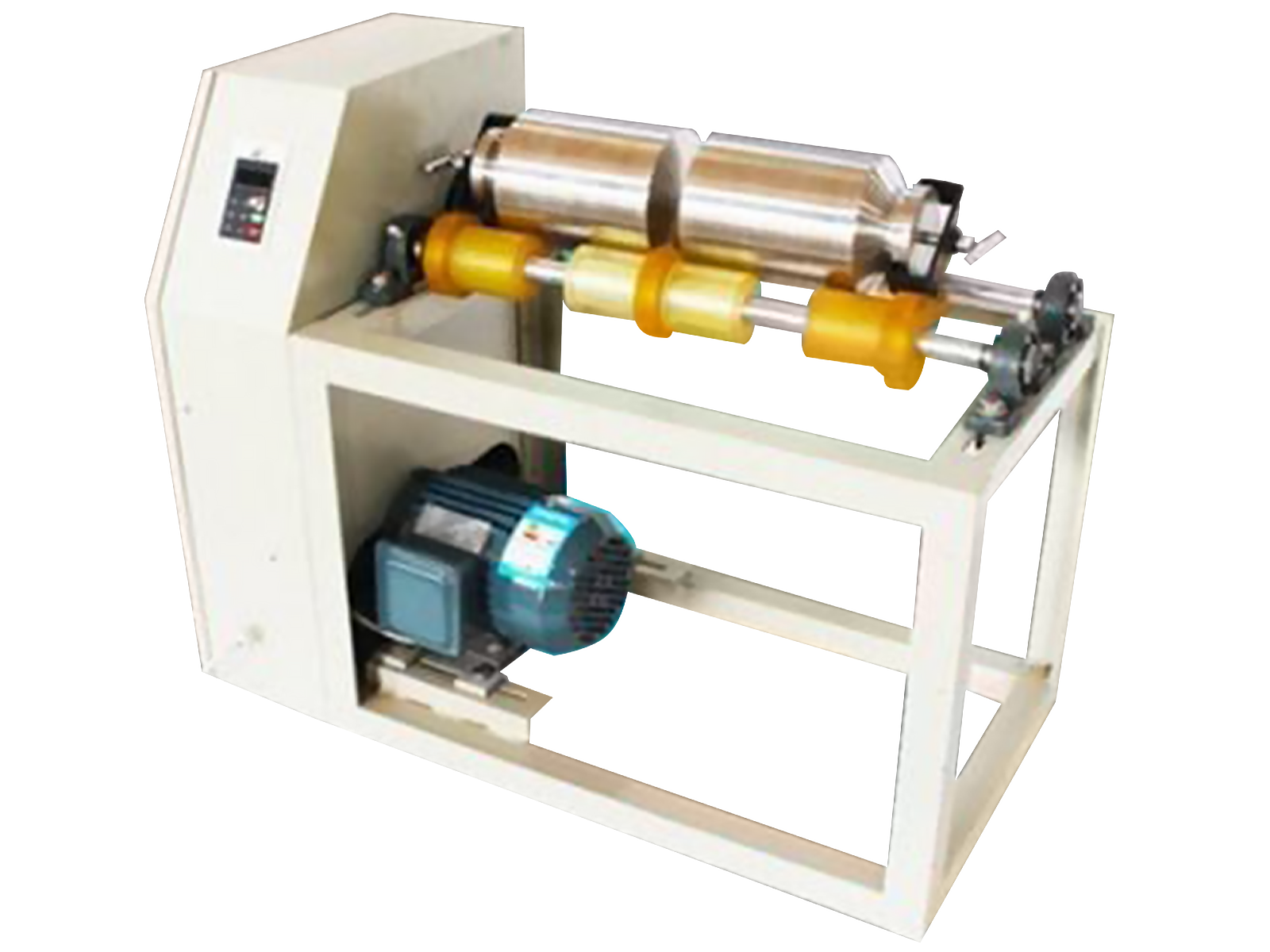

NANO PRO 4-Jar 8L Planetary Ball Mill

NANOSSR offers Planetary ball mill is a necessary device for mixing, fine grinding, small samples prepared, dispersion of nanomaterial, R&D of new product and small batch production for high tech materials. This equipment with small volume, comprehensive function, highly efficiency, low noise which is the ideal device of obtaining micro-particle research samples. It used for R&D institute, colleges and universities, enterprise laboratory (Four samples can be obtained at the same time in each experiment). The samples could be ground under vacuum state with using the vacuum ball mill jars. This Series uses the latest gear noise reduction technology and the completely closed oil seal patent technology noise isolation design to control the noise when running and is more stable than the ordinary planetary ball mill. Increase life by more than five times

Technical Specification

|

Name |

Planetary ball mill |

|

Model |

YXQM-8L (Oil seal mute) |

|

Field of Application |

Pharmaceuticals, food, geology, metallurgy, agriculture, glass, ceramics, aviation chemicals, biology, materials, lithium power, electronics, plants, biology and so on. |

|

Feed Material |

Medium or low hardness, hard, brittle, fibrous, viscous. |

|

Size Reduction Principle |

Impact, friction |

|

Application |

pulverizing, grinding, mixing homogenizing,mechanical alloying |

|

Main Disk Structure |

Planetary main disk gear soaked in lube oil, reduce noise. |

|

Standard |

CE |

|

Electrical Description |

110V/60Hz |

|

Material Feed Size |

|

|

Final Fineness |

|

|

Batch Size / Feed Quantity |

4 x 2L |

|

Grinding Jar Sizes |

50 ml /100 ml / 250 ml / 500 ml/1000ml/2L |

|

Vacuum Jar Size |

250 ml /500ml/1000ml/2L( Stainless steel) |

|

Feed Material Capacity |

660ml*4 |

|

Feed balls Capacity |

660ml*4 |

|

Sun Wheel Speed |

10 - 320 r/min |

|

Ball Mill Jar Speed |

20 - 640 r/min |

|

Total Grinding Speed |

960 /min |

|

Speed Ratio |

1:2 |

|

Material of Grinding Tools |

Stainless steel, agate, zirconia, corundum, tungsten carbide, nylon, polyurethane, polytetrafluoroethylene, silicon carbide, etc. |

|

Ball Size |

1 / 2 / 3 / 5 / 8 / 10 / 15 / 20 / 25 / 30 mm |

|

No. of Grinding Stations |

2 or 4 |

|

Mode |

Vertical planetary |

|

Grinding Mode |

Dry/wet |

|

Low Temperature CoolingOr Liquid NitrogenTreatment |

Yes (air cooler added) |

|

Oil Seal Position |

The bottom of planetary main disk |

|

Disk Dimensions |

420mm |

|

Oil Seal Capacity |

800ml(fill in before using the planetary ball mill) |

|

Noise |

|

|

Protection Code |

IP60 |

|

CN Patent |

Safety protection (No.ZL 2015 2 0836150.6) |

|

CN Patent |

Oil seal silent (Patent No.ZL 2014 2 0375569.1) |

|

CN Patent |

Frequency control(patent No.ZL 2016 2 0836150.6) |

|

W x H x D Closed |

80*60*75cm |

|

Net Weight |

220kg |

Our wide range of premium quality milling jars and milling media balls have excellent wear resistance and milling efficiency for powder milling, for customization please contact us.